Gate type five axis machining center

Category:

keys: Gate type five axis machining center

Product Description

I. Introduction

The G series CNC five axis gantry machining center is a technology intensive product designed and manufactured by our company for high-speed boring, milling, twisting, drilling and other five axis linkage CNC machining centers.

This machine tool can be used in civil and military industries such as machinery, automobiles, tools, molds, carving, clocks, footwear, power generation, ships, aerospace, precision instruments, etc.

The CNC five axis linkage gantry machining center has all the machining functions and capabilities of a multi face machining center. By selecting different cutting tools, it also has the ability to boring, milling, and drilling surfaces (flat, inclined, or curved surfaces) at any spatial position on the workpiece. So its process scope is wider and its functions are stronger.

Ⅱ.Mechanical structure

The mechanical structure of the G series CNC five axis vertical machining center is as follows:

III. Specification parameters

|

Parameter |

Unit |

VMC1580-50/63 |

VMC1890-63/80 |

||

|

X axis travel |

mm |

1500 |

1800 |

||

|

Y axis travel |

mm |

800 |

900 |

||

|

Z axis travel |

mm |

700 |

700 |

||

|

A axis travel |

° |

±120 |

|||

|

B axis travel |

° |

360 |

|||

|

Distance from spindle end face to worktable |

mm |

150-950 |

110-1010 |

||

|

Table size |

mm |

1500*800 |

1800*900 |

||

|

T-groove size (width x spacing x quantity) |

mm |

5-18/80 |

5-18/110 |

||

|

Max. weight of table |

kg |

800 |

1200 |

||

|

Size of rotary table (B-axis) |

mm |

630/800 |

|||

|

Spindle speed |

rpm |

15000/18000/2400 |

|||

|

Spindle motor power |

Kw |

25 |

|||

|

Spindle inner hole taper |

|

HSK-A63 |

|||

|

Three axis motor torque |

Nm |

20/20/27 |

|||

|

X axis fast movement speed |

m/min |

24/36 |

|||

|

Y axis fast movement speed |

m/min |

24/36 |

|||

|

Z axis fast movement speed |

m/min |

24/36 |

|||

|

A axis fast movement speed |

rpm |

20 |

|||

|

B axis fast movement speed |

rpm |

20 |

|||

|

feed rate |

mm/min |

1-10000 |

|||

|

X axis screw size (diameter x lead) |

mm |

50×12/16 |

50×12/16 |

||

|

Y axis screw size (diameter x lead) |

mm |

|

|

||

|

X axis screw size (diameter x lead) |

mm |

|

|

||

|

tool |

Tool capacity |

|

32/40 |

||

|

|

Max. blade diameter (full/empty) |

mm |

70/100 |

80/150 |

|

|

|

Max. tool length |

mm |

300 |

||

|

|

Max.tool weight |

kg |

8 |

||

|

|

Tool change time (knife knife) |

sec |

3 |

||

|

positioning accuracy |

mm |

0.006 |

|||

|

Repetitive positioning accuracy |

mm |

0.004 |

|||

|

A/B axis accuracy |

|

10"/4" |

|||

|

CNC system |

|

SIEMENS 840Dsl(ONE) |

|||

|

Total number of control axes |

Axes |

5 |

|||

|

Simultaneously controlled axes |

Axes |

5 |

|||

|

Overall weight |

kg |

10500 |

13500 |

||

|

External dimensions (length* width*height) |

mm |

3116*2260*2560 |

3516*2860*3100 |

||

IV. Standard attachments

1、Crux components

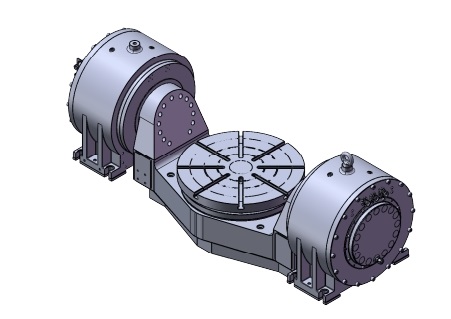

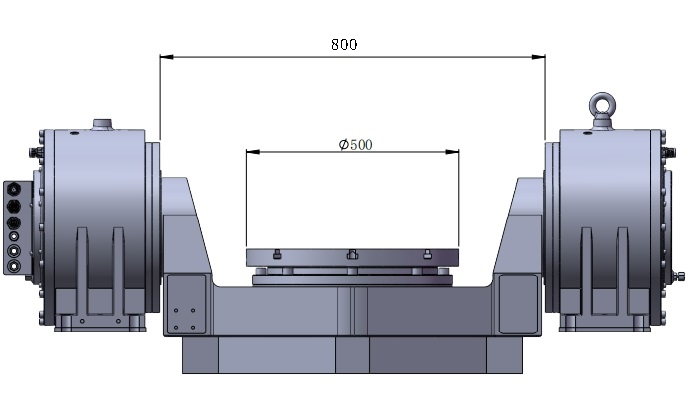

1)Cradle turntable

The external structure of the DF series CNC cradle turntable is as follows:

The external dimensions of the DF series CNC cradle turntable are as follows:

Technical parameters of DF series CNC cradle turntable:

|

project |

unit |

DF500H |

DF800H |

|

A shaft torque |

Nm |

1200 |

2200 |

|

A shaft speed |

rpm |

35 |

20 |

|

xis travel |

° |

±110(±120°) |

|

|

C shaft torque |

Nm |

710 |

1200 |

|

C shaft speed |

rpm |

50 |

20 |

|

C table size |

mm |

630 |

800 |

|

C axis travel |

° |

360 |

|

|

positioning accuracy |

" |

15" |

|

|

Repetitive positioning accuracy |

" |

4 |

|

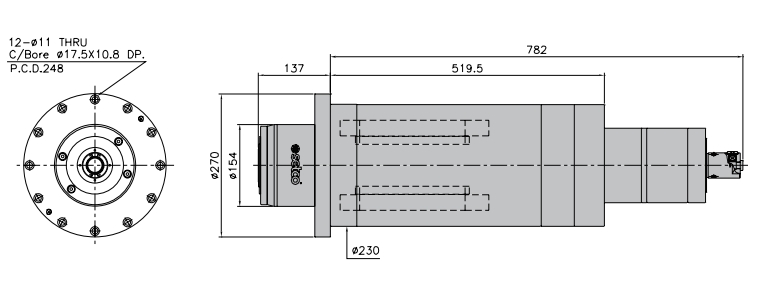

2)Electric spindle

The external dimensions of the electric spindle are as follows:

Parameters of electric spindle:

|

Specification |

225A |

|

|

Max. speed |

15000/16000/20000/24000 |

|

|

taper |

ISO#40 HSK A63 |

|

|

Bearing inner diameter |

¢70mm |

|

|

lubrication system |

Crease/Oil-Air |

|

|

external diameter |

¢230mm |

|

|

Nasal distance |

137mm |

|

|

Total length of spindle |

849.5mm |

|

|

Motor brand |

FANUC |

Ate |

|

Motor specifications |

Bil116M/20000 |

AC170/200 |

|

Motor power |

18.5/26kw |

25/29kw |

|

Motor torque |

95.5/120Nm |

83.2/99.3Nm |

|

Optional configuration |

CTs/Air shield |

|

3)CNC system

The CNC system uses 840Dsl (ONE) produced by SIEMENS in Germany or 220MA-5 produced by Taiwan's new generation company。

2、Universal components

1)Tool magazine

Select Taiwan Jifu and Okada knife depots. Specifically, as follows:

| Wheel type tool magazine | Chain type tool magazine |

|

|

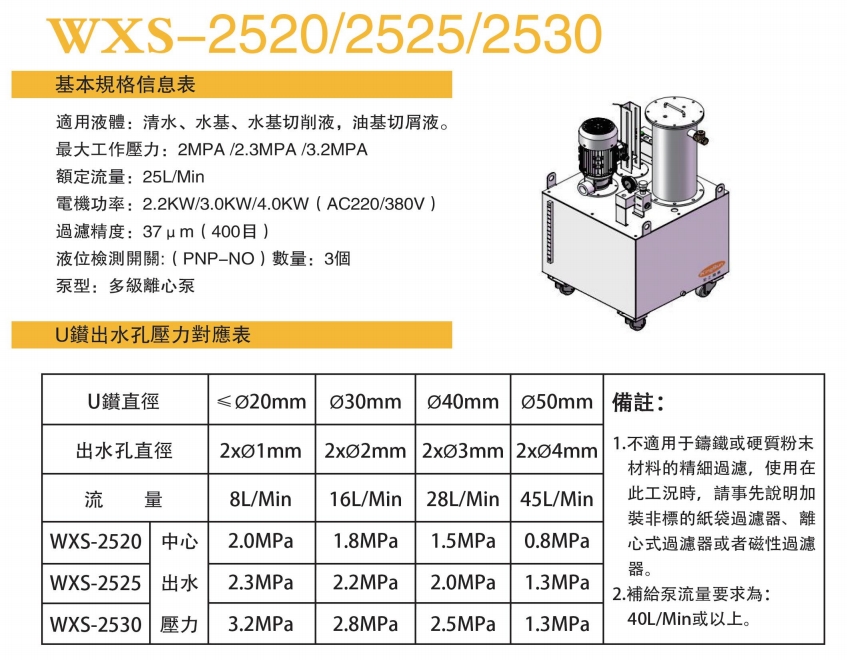

2)Central effluent filtration device

Select the WXS series filtration device produced by Taiwan Jinshang Precision Machinery Company, as follows:

3)Oil water separator

4)Electronic ruler

V. Optional accessoriess

Automatic tool measuring device

Automatic measurement system for workpieces

Related products

ONLINE MESSAGES

Our staff will contact you within 24 hours (working days)

Service hotline:+8615055979577

No.50 Gaocheng East Road, Economic and Technological Development Zone, Lu'an City, Anhui Province, China

E-mail:316932431@qq.com

Scanning the QR code

Copyright © 2024 Lu'an Jinte Machinery Co.ltd