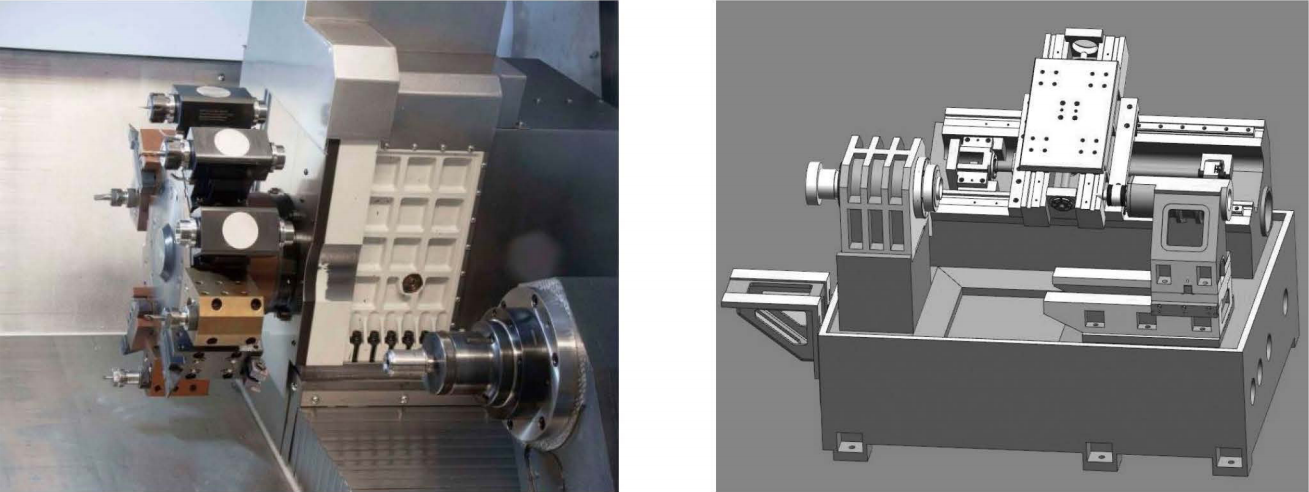

CNC-TY5045 turn-milling compound CNC lathe

Category:

keys: CNC-TY5045 turn-milling compound CNC lathe

Product Description

I. Introduction

CNC-TY5045 turning milling composite CNC lathe is a brand new product designed and produced in response to market and development needs, based on our factory's years of experience in designing horizontal CNC lathes.

The main performance indicators of this product have reached the international advanced level, including energy saving and environmental protection. Compared with similar machine tools, it has the following characteristics:

◆ 1. High efficiency: Short processing cycle, reducing non cutting time

◆ 2. High precision: good static accuracy and machining accuracy

◆ 3. High space efficiency: Small space maximizes its effectiveness

◆ 4. The X/Z axis adopts three-point positioning ball screws with high positioning accuracy. The X/Z axis adopts a linear guide rail design, which increases the guide rail and higher dynamic and static loads, improving the rigidity of the machine tool. This series of machine tools adopts an integrated structure of mechanical, electrical, and hydraulic components, with a reasonable overall layout. Advanced finite element analysis software is used to analyze and optimize the entire machine, achieving optimal performance; The key purchased parts are selected from internationally renowned manufacturers' standard series products to ensure the accuracy and reliability of the machine tool. Therefore, this series of machine tools is particularly suitable for industries such as automotive, motorcycle, electronics, and light industrial machinery to efficiently, massively, and precisely process rotating parts. The machining accuracy is IT6 level, and the Cp value is greater than or equal to

On 1.33.

Ⅱ.Internal structure

III.Machine Parameters

| 床身上最大回转直径(mm) Maximum turning diameter of the bed |

500 | |

| 托板上最大回转直径(mm) Maximum turning diameter on the pallet |

φ200 | |

| X 轴 最 大 行 程 ( mm ) X-axis maximum travel |

300 | |

| Z轴最大行程(mm) Z-axis maximum travel |

550 | |

| 至主轴端面最大距离(mm) Maximum distance to spindle end face |

600 | |

| X轴快速移动(m/min) X-axisfast movement |

20 | |

| Z轴快速移动(m/min) Z-axisfast movement |

20 | |

| 主轴 Spindle |

2 0 0 主 轴 单 元 200 spindle unit |

|

| 主轴转速(rpm) Spindle speed |

3000(单元) 3000(unit) |

|

| 主轴端部规格 Spindle end Specification |

A2-6(单元) A2-6(unit) |

|

| 主 轴 通 孔 直 径 ( mm ) Spindle through hole diameter |

66 | |

| 丝杠规格 Screwspecifications |

X 轴 | 3210 |

| Z轴 | 4010 | |

| 丝杠头部直径 Diameter of lead screw head |

X轴 | 22 |

| Z 轴 | 22 | |

| 系统配置 System Configuration |

广 数 / 可 选 Wide/Optional |

|

| 丝杠品牌 Lead screw brand |

万 润 ( C 3 级 ) Wanrun(Grade C3) |

|

| 直线导轨型号 Linear guide model |

X 轴 | 35 |

| Z 轴 | 35 | |

| 直线导轨品牌 Linear Guide Brand |

德国FZS(P级) German FZS (Class P) |

|

| 电机止口规格 Specificationof motor stop |

X 轴 | φ110 |

| Z 轴 | φ110 | |

| 刀架形式 Tool holder form |

8 0 液 压 伺 服 刀 塔 80 hydraulic servo turret |

|

| 刀 方 尺 寸 ( mm ) Cube dimensions |

25 | |

| 床身形式 Bed form |

30°斜床身 30°0blique bed |

|

| 尾座动力 Tailstock power |

液压紧顶 Hydraulic Tight Top |

|

| 尾座导轨 Tailstock rail |

硬轨 Hard rail |

|

| 机床总重量(kg) Total weight of machine tool |

3600 | |

| 外观尺寸(长x宽x高)(mm) Appearance size(lengthxwidthxheight) |

2290x1510x1700 (高度不包含报警灯) (Altitudedoes not include warning light |

|

| 夹紧方式 Clamping mode |

液 压 夹 头 / 卡 盘 可 选 Hydraulic clamping/Chuck |

|

Related products

ONLINE MESSAGES

Our staff will contact you within 24 hours (working days)

Service hotline:+8615055979577

No.50 Gaocheng East Road, Economic and Technological Development Zone, Lu'an City, Anhui Province, China

E-mail:316932431@qq.com

Scanning the QR code

Copyright © 2024 Lu'an Jinte Machinery Co.ltd