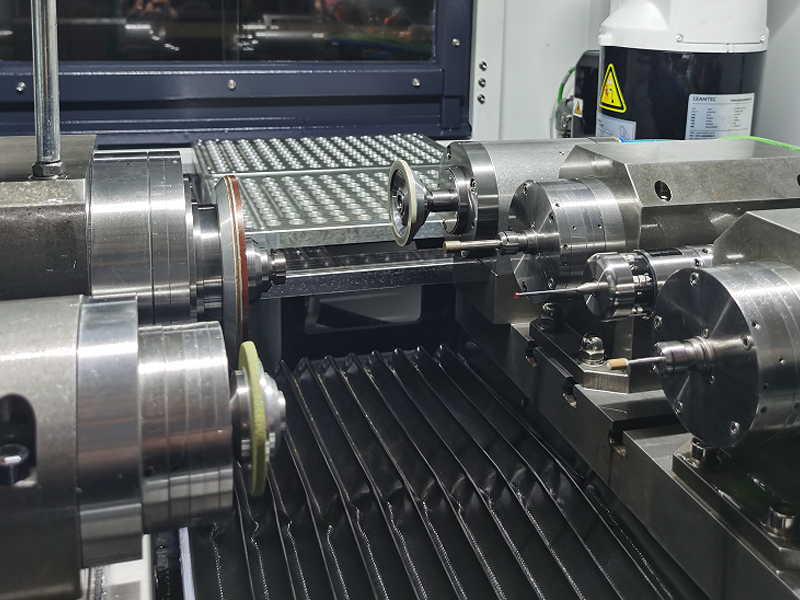

ZCS-QGM2030B5 High precision inner circle (thread) CNC grinder

keys: ZCS-QGM2030B5 High precision inner circle (thread) CNC grinder

Product Description

Technical characteristics of the equipment:

● Suitable for metal, tungsten steel, ceramic and other materials of ball screw nuts and other inner thread grinding processing, as well as tiny inner hole, cone hole, inner step hole, outer circle, end surface grinding grinding processing.

● The large guide thread can be processed through the optional large guide grinding shaft.

● The grinding machine using air static pressure workpiece electric spindle, ultrasonic air static pressure wheel electric spindle, air static pressure wheel dressing electric spindle, X / Z axis ultra precision air float rail, using the "nano carbon fiber material" of high rigidity, large bearing, low consumption, self-lubrication, not wear high precision air static pressure spindle and air static pressure rail, has the characteristics of low carbon green environmental protection.

|

Product name |

High precision inner circle (thread) CNC grinder |

||

|

Model |

Z CS-Q G M2030B 5 |

||

|

Intellectual property rights (invention patent) |

① An inner or outer round ultra-precision grinder of pneumatic static metal parts, Patent No.201110213261.8 ② A suitable for ultra-precision detection or ultra-high precision processing equipment gas floating guide rail, patent no. 201510300840.4 ③ An ultrasonic gas static piezoelectric spindle, Patent No.2019111228692 |

||

|

Scope of application |

Metal, tungsten steel, ceramic and other materials of ball screw nuts and other inner thread grinding processing, as well as tiny inner hole, cone hole, inner step hole, outer circle, end surface grinding grinding processing. |

||

|

Grinding inner diameter range (mm) |

1~120 |

||

|

Maximum grinding inner length (mm) |

100 |

||

|

Range of cone surface angle (degree) |

15°~ 180° |

||

|

Rowing angle of header (degree) |

45° |

||

|

Grinding pitch range (mm) |

0.5~10 |

||

|

1 # grinding wheel tilt angle (°) |

±10° |

||

|

Working accuracy |

Roundness (μm) |

0.3 |

|

|

Cylindricity (μm) |

2 Full trip |

||

|

Surface rough (Ra / μ m) |

0.1 |

||

|

Electric spindle of the inner round grinding wheel |

Rotation accuracy <0.2um, axial head radial beating 0.3um and axial beating 0.3um |

||

|

Workpiece electric spindle |

|||

|

The grinding wheel trim the electric spindle |

|||

|

Workpiece electric spindle |

High stiffness gas static pressure permanent magnet synchronous electric spindle, rated speed 3000 rpm, 3.7KW, 12 Nm, synchronous drive infinite speed regulation. Using precision pneumatic three claw chuck, and built-in precision diaphragm stylet. |

||

|

Electric spindle of ultrasonic inner round grinding wheel |

Ultrasonic gas-static pressure electric spindle, speed range of 80,000 rpm, 2 level, 1.5KW,0.18Nm, frequency converter drive infinite speed regulation. Swiss high precision ER11~16 spring singlet is installed into the sand wheel straight rod. |

||

|

Sand wheel axle |

Ultrasonic aerostatic inner diameter electric spindle 1 # |

5000~36000rpm,5.5KW, 1.46 Nm, asynchronous motor, frequency converter drive stepless speed regulation. The grinding wheel rod adopts external thread straight rod + ER11 conversion rod. |

|

|

Ultrasonic gas hydrostatic pressure internal diameter electric spindle 2 # |

30000~80000rpm,1.5KW,0.18Nm, Asynchronous motor, frequency converter drive infinite speed regulation. Swiss high precision ER11~16 spring singlet is installed into the sand wheel straight rod. |

||

|

Astatic OD electric spindle 3 # |

3000~24000rpm,5.5KW, 1.46 Nm, Asynchronous motor frequency converter drive stepless speed regulation. The grinding wheel rod is installed with 20 diameter grinding wheel clamp. |

||

|

Ultrasonic static internal diameter electric spindle (optional) |

3000~24000rpm, 15KW, 5.97 Nm, synchronous motor, frequency converter drive stepless speed regulation. The grinding wheel rod adopts external thread straight rod + ER11 conversion rod. |

||

|

CBN emery wheel dresser |

Dedicated for aerostatic piezo spindle 1.5KW, 12000rpm for CBN grinding wheel trimming. Mounted at the front of the head frame. |

||

|

Ultrasonic grinding function |

The built-in ultrasonic mechanism of the grinding wheel can automatically control the conversion of ultrasonic operation. |

||

|

Lead rail |

X axis guide rail |

Adopt ultra-precision air floating guide rail, straightness 1um / full travel. |

|

|

Z axis guide rail |

Adopt ultra-precision air floating guide rail, straightness 1um / full travel. |

||

|

X axle (mm) |

Germany Hedham high precision grating ruler, high precision linear motor drive, the maximum stroke of 400. |

||

|

Z axle (mm) |

Germany Hedham high precision grating ruler, high precision linear motor drive, the maximum stroke of 300. |

||

|

CNC control system (μ m) |

The German Siemens 828D high precision CNC system with a resolution of 0.1 μ m. |

||

|

Linear motion actuator |

Singapore Yakobis high-precision high-thrust U-core linear motor, water cooling. |

||

|

AE sensor (optional) |

SBS fluid AE sensor, installed at the front of the workpiece shaft for emptying and collision prevention. Improve the processing efficiency. |

||

|

Online measurement (optional) |

Configure contact displacement sensor head with one-way repeated measurement accuracy ± 1um. |

||

|

Center cooling of the workpiece spindle |

The workpiece spindle has a central cooling hole, the coolant enters the front end of the spindle, the cooling effect is good. |

||

|

Robot loading and unloading device (optional) |

The robot double-claw manipulator loading and unloading device is used to realize automatic loading and unloading. |

||

|

Lathe bed |

Natural granite, fully enclosed hood. |

||

|

Feed amount per grid of the handwheel (mm) |

0.001 |

||

|

Workpiece cutting oil cooling and filtration system |

Independent water (oil) cooling mode, equipped with paper bag and magnetic filtration, and cooling coil filtration circulation water tank. |

||

|

Water-cooling unit cooling system |

An independent water cooler is configured to cool the electric spindle and linear motor by cutting the liquid coil cycle, and the cooling capacity is 1.5KW. |

||

|

Compressed air cold dryer |

Independent electric spindle chiller with air treatment capacity of 1.5m³ / min |

||

|

Compressed air |

The compressed air supply pressure range is 0.5-0.6Mpa, and the total gas consumption is less than 200 L/min |

||

|

External parameter |

Working pressure 0.5~0.7Mpa, power supply 380V, 50Hz, the installed power 18KW |

||

|

Overall size 198016802080m m, net weight 2200 Kg |

|||

|

Order number |

Configure |

Quantity |

Specification details |

Vender |

|

1 |

Numerical control system |

A set |

828D bus type, resolution of 10nm |

Germany |

|

2 |

Linear motion actuator |

Two sets |

U-type high-thrust AUM 5-S4 |

Singapore |

|

3 |

Grating ruler |

Two sets |

420 / 320, ± 3um, and 10nm resolution |

Germany |

|

4 |

AC contactor and other electrical components |

A batch of |

380V/220V/24V |

France |

|

5 |

Frequency conversion drive |

Five sets |

2.2KW *2/3.7KW *1/5.5KW *1/15KW *1 |

Taiwan / Domestic |

|

6 |

Workpiece electric spindle |

1 Only |

3.7W/12Nm/3000rpm |

Domestic |

|

7 |

Electric spindle of inner grinding wheel 1 # |

A set |

Ultrasonic wave 5.5KW/1.46Nm/36000rpm |

Domestic |

|

8 |

Ultrasonic inner grinding wheel electric spindle 2 # |

A set |

Ultrasonic wave 1.5KW/0.18Nm/80000rpm |

Domestic |

|

9 |

Outer round grinding wheel electric spindle 3 # |

A set |

Ultrasonic wave 15KW/5.97Nm/24000rpm |

Domestic |

|

10 |

Air static pressure grinding wheel trim the electric spindle |

A set |

1.5KW/1.2Nm/12000rpm |

Domestic |

|

11 |

Gas floating guide rail Z axis |

Pay 1 |

Full trip 1um |

Domestic |

|

12 |

Air floating guide rail X axis |

Pay 1 |

Full trip 1um |

Domestic |

|

13 |

Electric cabinet air conditioner |

A |

MCA-03H-01-1225 |

Domestic |

|

14 |

Air freeze-dryer |

A |

1.5m³/min |

Domestic |

|

15 |

Air-based precision pressure-reducing valve |

Two sets |

RPE1000-8-04 |

Japan |

|

16 |

AE sensor (optional) |

A |

AE-1000 Fluid |

America |

|

17 |

Robot loading and unloading device (optional) |

A set |

Six joints, double claw type |

Taiwan |

|

18 |

On-line measurement |

A set |

Repeated measurement accuracy was ± 1um |

Domestic |

|

19 |

Oil mist collector |

A |

Electrostatic type ET-1200 |

Domestic |

|

20 |

Lathe bed |

A set |

Natural granite |

Domestic |

Related products

ONLINE MESSAGES

Our staff will contact you within 24 hours (working days)

Service hotline:+8615055979577

No.50 Gaocheng East Road, Economic and Technological Development Zone, Lu'an City, Anhui Province, China

E-mail:316932431@qq.com

Scanning the QR code

Copyright © 2024 Lu'an Jinte Machinery Co.ltd