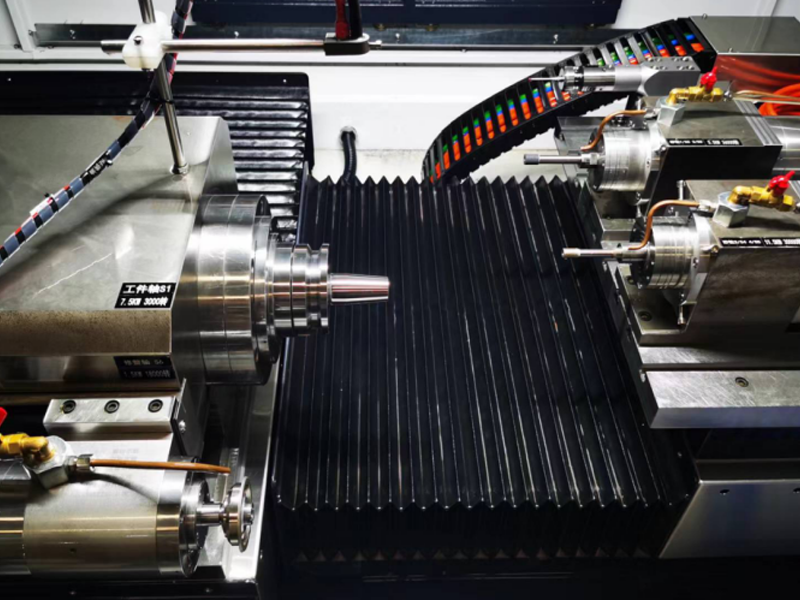

ZCS-QGM3050B5 Three grinding head ultra-precision air static pressure inner circular CNC grinder

keys: ZCS-QGM3050B5 Three grinding head ultra-precision air static pressure inner circular CNC grinder

Product Description

"ZCS-QGM3050B 5 ultra-precision air static pressure circular CNC grinder", Workpiece shaft adopts high-precision aerostatic pressure electric spindle, Double coarse grinding wheel shaft with high rigidity ceramic ball bearings, Double precision grinding 80,000 rpm grinding wheel shaft using high precision ultrasonic, aerostatic piezoelectric spindle, The grinding wheel trimming adopts a high-precision aerostatic piezoelectric spindle, X / Z axis rail adopts high precision gas floating rail + linear motor, The new generation of 21A precision CNC system, Faghigh precision grating ruler in Spain, On-line type detector, AE elimination, anti-collision sensor, Air spring shock absorption device, And the temperature and air pressure control, Constitute a full closed-loop control system. Make the whole machine reach the machining accuracy of 0.5um circle and 2um cylinder. The workpiece card adopts precision three-claw chuck, or BT50 knife handle automatic loose knife mechanism fixture, special Latin can be connected with BT40 / BT30 / HSK and other transition sets, so that the whole machine has a variety of clamping capabilities, as well as higher and faster processing efficiency. The specific technical parameters are shown as follows.

|

Product name |

Ultra-precision air-static pressure inner circular CNC grinder |

|

|

Model |

ZCS-QGM3050B 5 |

|

|

Patent of invention |

① An inner or outer round ultra-precision grinder of pneumatic static metal parts, Patent No.2011102132 ② A gas-floating guide rail suitable for ultra-precision detection or ultra-high precision processing equipment, Patent No.2015103008 ③ An ultrasonic gas static piezoelectric spindle, Patent No.201911122 |

|

|

Trademark |

ZCS |

|

|

Scope of application |

Grinding processing of inner hole, cone surface, end surface and multi-order inner hole |

|

|

Processing of aperture range (mm) |

2-100 |

|

|

Maximum loading length (mm) |

300 |

|

|

Maximum grinding hole depth (mm) |

150 |

|

|

Workpiece shaft and guide rail center height (mm) |

210 |

|

|

Rowing angle of header (degree) |

±10° |

|

|

Working accuracy |

Roundness (μm) |

0.5 |

|

Cylindricity (μm) |

2 |

|

|

Surface rough (Ra / μ m) |

0.1 |

|

|

Workpiece electric spindle |

The tation accuracy was <0.2um, axial head radial beating 0.3um, and axial movement 0.3um |

|

|

Electric spindle 1 # (optional) |

High precision air static pressure, ultrasonic ac asynchronous electric spindle, speed range of 80,000 rpm, 1.5KW, frequency converter drive infinite speed regulation. The grinding wheel rod is clamped with Swiss high precision ER11 spring singlet. |

|

|

Electric spindle 2 # (optional) |

High rigidity ultrasonic gas electrostatic voltage spindle, the highest speed of 40,000 rpm, 5.5KW, frequency converter drive infinite speed regulation. The grinding wheel connecting rod is connected with M141.5 external thread, and ER11 or M2 internal wire is connected with the grinding wheel. |

|

|

Electric spindle 3 # (optional) |

High rigidity ultrasonic gas electrostatic voltage spindle, the highest speed of 24,000 rpm, 15KW, frequency converter drive infinite speed regulation. The grinding wheel connecting rod is connected with M201.5 external thread, and the grinding wheel and the nuts are pressed or glued with the connecting rod. |

|

|

Workpiece electric spindle |

High precision gas static pressure permanent magnet synchronous electric spindle, 24 Nm, 3000 / 5000 rpm, 13A,7.5KW, built-in encoder, synchronous drive drive stepless speed regulation. Configure special fixture, can also install K125 precision three claw caruck. |

|

|

Emery wheel dresser |

Equipped specifically for diamond grinding wheel repair gas hydrostatic pressure electric spindle 1.5KW, 12000rpm. |

|

|

Lead rail

|

X-axis gas-floating guide rail stiffness |

Adopt ultra-precision air floating guide rail, with straightness of 1um / full travel. |

|

Z-axis gas-floating guide rail stiffness |

Adopt ultra-precision air floating guide rail, with straightness of 1um / full travel. |

|

|

X axle (mm) |

X-axis rail length is 1000mm, maximum stroke is 500 and resolution is 0.1 μ m |

|

|

Z axle (mm) |

Z axis rail length is 750mm, maximum stroke 400 and resolution 0.1 μ m |

|

|

CNC feed system (μ m) |

A new generation 21A precision CNC system was applied with a resolution of 0.1 μ m. Optional Siemens 828D system. |

|

|

Linear motion actuator |

The X / Z axis is driven by high precision linear motor. |

|

|

Grating ruler |

The X / Z axis adopts a Spanish grid grating ruler with a resolution of 0.1 μ m. Optional Hedham raster ruler. |

|

|

Online measurement (optional) |

Middle figure wireless contact displacement sensor measuring head, field comprehensive repeated measurement accuracy ± 1um..5 An online pneumatic meter can also be selected. |

|

|

AE sensor (optional) |

For grinding wheel grinding air elimination process, and collision prevention, can effectively improve the efficiency. |

|

|

Y / Z axis positioning accuracy (μ m) |

±2 |

|

|

Y / Z axis (μ m) |

±1.5 |

|

|

Feed amount per cell of the handwheel (mm) |

0.001 |

|

|

Water-cooling unit cooling system |

An independent water cooler is configured to cool the electric spindle and linear motor by cutting the liquid coil circulation, and the cooling capacity is 1.5KW. |

|

|

Workpiece cutting oil cooling and filtration system |

Use independent water (oil) cooling mode, equipped with paper bag and magnetic filtration, and cooling coil filtration circulation water tank. |

|

|

Water and oil mist collector |

Independent water and oil mist collector to filter the water and oil mist air in the hood. |

|

|

Lathe bed |

The bed body and support plate are made of high quality natural granite. |

|

|

Compressed air |

The compressed air supply pressure range is 0.45-0.66Mpa, and the total gas consumption is 200L / min |

|

|

External parameter |

Operating pressure 0.45~0.8Mpa, power 380V, 50Hz, complete power 28KW |

|

|

Overall size 280017002200 (including base and electrical box), net weight 3200 Kg |

||

3. Main technical parameters of the whole machine

Iv. Main configuration list

|

Order number |

configure |

Quantity |

Specification details |

Vender |

|

1 |

Numerical control system |

A set |

21A, and the bus formula vs |

Taiwan |

|

2 |

Linear motion actuator |

Two sets |

U-type high-thrust AUM 5-S4 |

Singapore |

|

3 |

Absolute grating ruler |

Two sets |

Resolution of 0.1 μ m |

Spain |

|

4 |

AC contactor and other electrical components |

A batch of |

380V/220V/24V |

France |

|

5 |

Frequency conversion drive |

Four |

2.2KW ×2/5.5KW /11KW/15KW |

Taiwan / Domestic |

|

6 |

Electric spindle of pneumatic static pressure workpiece |

1 Only |

7.5K W/24Nm/3000/6000rpm |

Domestic |

|

7 |

Electric spindle of round grinding wheel in air-static pressure 1 # |

A set |

Ultrasonic wave 1.5KW/0.18Nm/80000rpm |

Domestic |

|

8 |

Electric spindle of pneumatic static inner round grinding wheel 2 # |

A set |

Ultrasonic wave 5.5KW/1.3Nm/40000rpm |

Domestic |

|

9 |

Electric spindle of inner round grinding wheel 3 # |

A set |

Ceramic ball: 15KW / 6 Nm / 24,000 rpm |

Domestic |

|

10 |

Air static pressure grinding wheel trim the electric spindle |

A set |

1.5KW/1.2Nm/12000rpm |

Domestic |

|

11 |

Gas floating guide rail Z axis |

Pay 1 |

Full trip 1um |

Domestic |

|

12 |

Air floating guide rail X axis |

Pay 1 |

Full trip 1um |

Domestic |

|

13 |

Air-based precision pressure-reducing valve |

Two sets |

RPE1000-8-04 |

Japan |

|

14 |

Online detection probe (optional) |

A set |

± 1.5um wireless |

Domestic |

|

15 |

AE sensor (optional) |

A set |

AE-1000 Fluid |

America |

|

16 |

Electric cabinet air conditioner |

A |

MCA-03H-01-1227 |

Domestic |

|

17 |

Electric spindle water cooling unit |

A |

ACW-025 |

Domestic |

|

18 |

Cutting fluid paper bag filter cooler |

A |

100L |

Domestic |

|

19 |

Compressed air cold dryer |

A |

1.5m² |

Domestic |

|

20 |

Oil mist collector |

A |

FC-1400 |

Domestic |

|

21 |

Marble bed body |

A set |

Natural granite |

Domestic |

Related products

ONLINE MESSAGES

Our staff will contact you within 24 hours (working days)

Service hotline:+8615055979577

No.50 Gaocheng East Road, Economic and Technological Development Zone, Lu'an City, Anhui Province, China

E-mail:316932431@qq.com

Scanning the QR code

Copyright © 2024 Lu'an Jinte Machinery Co.ltd