Recommended Products

Strict quality control, to create trustworthy products for you

Lu'an Jinte Machinery Co.

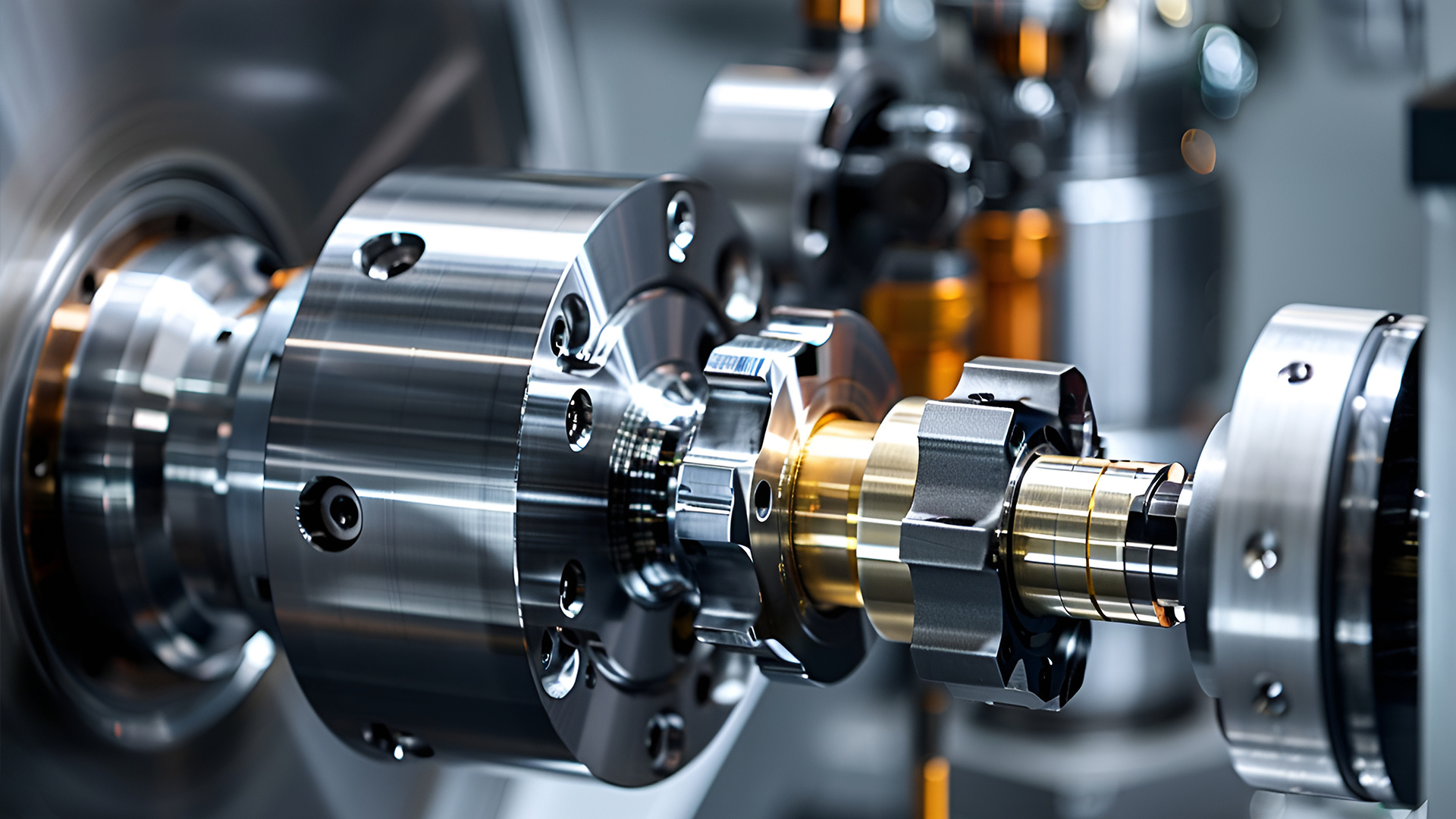

Our company produces vertical CNC grinding machines and acts as an agent for products that are the advantageous products of China's domestic cutting-edge equipment production factories; for example, five-axis machine tool series; turning and milling machine tool series; machining center series; gantry machining center series (movable column, movable beam, movable table); gantry guideway grinding series; grinder series (internal cylindrical grinding series, external cylindrical grinding series; composite grinding series; surface grinding series; endface grinding series; thread grinding series; precision miniature internal cylindrical grinding system; turning and grinding composite machine tools); and turning machine tool series.

Industry experience

Professional talents

Cooperative clients

Sales area

WHY CHOOSE US

THE COMPANY'S PRODUCTS MEET INTERNATIONAL STANDARDS

Our company produces vertical CNC grinding machines and the products we represent are all advantageous products of domestic cutting-edge equipment production factories in China

View More +

Company purpose

Based on China, to the world!

Company goal

To do a good job with the heart of the product, to meet the customer's equipment purchasing requirements!

For customer service

Choose Jinte company in China do not have to worry about how to choose machines and equipment!

NEWS CENTER

Basic parts and basic components for machining centers

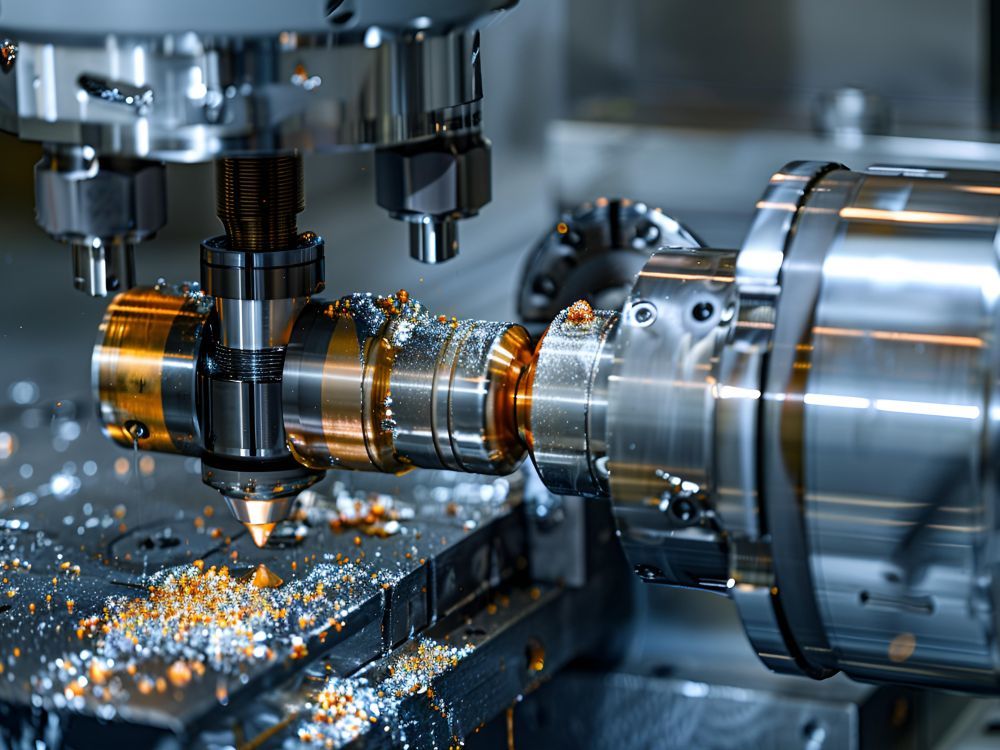

Machining centers can generally be divided into two parts: the machine tool (mechanical part) and the control system (electrical part). The machine tool is the main body of the machining center, and the control system is the core of the machining center. Machining centers are usually composed of basic parts (bed, table, column), spindle parts, CNC system, automatic tool changing system and auxiliary devices.

2024-04-01

Features and machining principles of machining centers

Machining centers are equipped with tool magazines and can automatically change tools, which can realize multi-process machining of workpieces. After the workpieces are clamped at one time, the numerical control system can control the machine tool according to different processes, automatically selecting and replacing the tools, adjusting the spindle speed, feed, and motion trajectory. Modern machining centers to a greater extent so that the workpiece in a clamping, to achieve multi-surface, multi-featured, multi-station continuous, efficient, high-precision machining, that is, process concentration. This is the most prominent feature of the machining center.

2024-04-10

How to operate and use CNC surface grinder correctly?

CNC Surface Grinder is a kind of machining equipment, which is used to process all kinds of materials for flat surface precision machining. Characterized by high precision, high efficiency and intelligent operation, this equipment is widely used in the manufacturing industry. However, due to the complexity of the equipment's structure and operating requirements, incorrect operation may lead to serious safety issues and equipment failure. Therefore, the correct operation and use methods are very important. In this article, we will introduce the correct operation and use method of CNC surface grinder.

2024-01-18

Service hotline:+8615055979577

No.50 Gaocheng East Road, Economic and Technological Development Zone, Lu'an City, Anhui Province, China

E-mail:316932431@qq.com

Scanning the QR code

Copyright © 2024 Lu'an Jinte Machinery Co.ltd